Do-it-yourself servicing and maintenance for practical owners

The object of this website is not just to record what must be done and when to do it;a manufacturer's handsite does that quite adequately.

Here, in addition to the usual maintenance details, an attempt is made to explain the "whys" and "wherefores" of the various jobs not only for the benefit of the comparative novice but also for the fairly experienced owner who is likely to tackle such work as decarbonizing and valve-grinding, brake-relining or attentions to the carburettor and ignition system, which do not call for the use of expensive service tools or equipment.

The average handbook either ignores these jobs or dismisses them somewhat arbitrarily as the province of the local dealer which can be infuriating to a practical owner who possesses a reasonable range of hand tools and the ability to follow straightforward instructions!

A chapter has been added which deals, in addition to strictly practical matters, with engine tuning kits and some worthwhile accessories subjects which are likely, sooner or later, to engage the attention of any enthusiast.

Thanks are due to B.L.M.C. and to a number of other firms that have supplied information and illustrations, and in particular to Mr. David Lambert, of Lambert's Garage, St. Osyth, for providing facilities for taking the majority of the photographs actually "on the job."

Sunday 18 October 2009

Car Care and Service Manual

Labels: accessories, car, care, engine, handbook, manual, manufacture, service

Posted by Info Mini Cars at 04:53 0 comments

Getting to know your car

When the Austin Seven and Morris Mini-Minor were introduced in 1959, after eight years of design and development, they caused a sensation in the motoring world for the new B.M.C. Minis bristled with unconventional ideas, but were nevertheless essentially practical in conception. Soon the original Austin and Morris Minis were joined by the Wolseley Hornet and the Riley Elf, together with the redoubtable Cooper and Cooper "S" versions which immediately established themselves as giant-killers in the racing and competition worlds.

In October 1967 came the Mini "1000" Mark II models, with 998 c.c. engines, and in October 1969, ten years and two million Minis after the introduction of the original cars, the more refined and comfortable Clubman and 1275 GT models. These were followed, in November 1969, by two new "basic" Minis—the 850 and the 1000—which retained the old bodyshell but incorporated the wind-up windows, concealed hinges and the negative-earth electric system of the Clubman.

The Mini 850, 1000, Clubman, Clubman Estate, 1275 GT and the Cooper "S" therefore comprised the complete Mini range, the Austin, Morris, Wolseley and Riley variants being discontinued and the cars being known simply as Minis in their own right.

To what do the Minis owe their astonishing success? It was their designer, Alec Issigonis, who best summed it up when he remarked, in effect, "We have deliberately made the cars very small outside, because we have found new ways of making them very large inside."

How was this done, and how does it affect the owner who proposes to carry out as much maintenance as possible in the home garage? First, there is the arrangement of the combined engine and transmission unit transversely across the front of the car. Besides saving a great deal of space, this has rendered all the usual items that require attention (except possibly the ignition distributor) unusually accessible; the owner should have no difficulty in carrying out normal adjustments and all work short of a major overhaul (which calls for removal of the engine).

Admittedly the ignition equipment, being mounted at the front of the engine without protection from a radiator, is liable, on earlier models, to be swamped by a bow wave if a water-splash is negotiated too enthusiastically, and cutting-out of the ignition can also occur when driving in heavy rain. Simple methods of waterproofing the ignition system are, however, discussed in Chapter 7. The engine and transmission assembly share a common supply of oil. Instead of having to check and top-up three oil levels, the work is confined to checking the level on the usual engine dipstick and adding fresh oil through the filler on the valve cover. A similar saving in time and trouble applies, of course, when it is necessary to drain the oil.

Notice, also, that air is forced through the side-mounted radiator from the engine side, emerging by way of the nearside wheel arch, which means that the engine is not surrounded by preheated air .The technically-minded reader will appreciate that this might lead to carburettor icing in cold weather but will note that this can be taken care of, on most models, by positioning the inlet to the air cleaner close to the exhaust manifold. A pre-heated air intake does, of course, result in the loss of a small amount of power under full-throttle conditions, but this is more than compensated for by improved flexibility and better fuel consumption over a wide range of running conditions and in hot weather the intake can be swung away from the manifold.

Again there is evidence of the combination of technical and practical considerations in the use of hollow rubber cones as suspension units instead of steel coil or leaf springs. Rubber springs not only have excellent self-damping properties, giving a particularly good "ride," but require no lubrication and cannot develop squeaks or broken leaves! The Hydro-lastic suspension fitted to later cars, which is described in Chapter 9, takes the principle a stage further by interconnecting the front and rear suspension units, giving a level, pitch-free ride that is outstanding for such a small vehicle.

One could continue to point out examples of the way in which technical advantages have been combined with practical features throughout the car. It is necessary, however, to turn now to a brief description of the functioning of the various instruments and controls, followed by notes on the handling characteristics of the various models. The information is intended mainly for the benefit of an owner who is anxious to get the best from his car; it does not come into the category of elementary driving instruction, as this is a subject which is obviously the province of a fully-qualified instructor.

Labels: car, cooper, equipment, getting, know, mini, radiator, suspansion, transmission, waterproofing

Posted by Info Mini Cars at 04:52 0 comments

Towing the Car

The car should never be towed with the front wheels on the ground if a transmission fault is suspected. Garage assistance should be obtained as it is necessary to lift the front end of the vehicle on a suitable towing rig. In other cases the car can be towed normally but the selector must be at N and the ignition should, of course, be switched off.

Labels: car, fault, towing, transmission

Posted by Info Mini Cars at 04:50 0 comments

Emergency Starting

If the battery has insufficient charge to turn the engine over with the starter motor but is providing sufficient current to operate the ignition system, it is not possible to start the car in the usual way by enlisting the aid of friends to push it at a relatively low speed with top gear engaged, since the slip in the torque converter will be1 sufficient to prevent the engine rotating. It will be necessary to tow the car at a speed of about 20 m.p.h. before the transmission will drive the engine. If this can be done, the drill is to set the mixture control, if necessary, switch on the ignition and select second gear manually when a speed of 20 m.p.h. is reached. Then depress the accelerator sufficiently to enable the engine to start. If the engine is new and has not completed its running-in period, however, a road speed of about 30 m.p.h. must be reached and D must be selected.

The Automatic-transmission Models

The automatic transmission which is available on the Austin and Morris Minis provides two-pedal, fully-automatic motoring or complete manual control of the gears, at the choice of the driver. It is particularly well suited to the Mini, since it gives four gear ratios instead of the two or three provided by most other types of automatic transmission. A hydraulic torque converter replaces the clutch and ensures a very smooth take-up of the drive from a standstill and when changing gear.

Driving the "automatic" Mini is delightfully simple if the gear lever is moved to the D position, after starting the engine with the lever at N (an automatic cut-out ensures that the starter mechanism can operate only when the selector is at Neutral). With D or Drive engaged, the trans-mission will change up at speeds which depend on the amount of throttle opening, but the maximum engine revs are limited by a governor in the transmission to the equivalent of about 22 m.p.h. in first gear, 34 m.p.h, in second, and 50 m.p.h. in third.

When maximum acceleration is required, a "kick-down" switch which comes into action at the extreme limit of the throttle-pedal travel will engage the next lowest gear, the maximum speed limits for a kick-down change being approximately 17, 28 and 40 m.p.h. in first, second and third gears respectively.

Probably the most attractive feature of the transmission for the keen driver, however, is the fact that downward changes can be made instantly and very smoothly simply by moving the gear lever to the appropriate position. A "zig-zag" between the second and third gear positions acts as a stop when changing from top to third, preventing accidental engage¬ment of second gear, which might over-speed the engine. The main point to remember, in fact, when controlling the gearbox manually, is not to change down at a road speed which is above the safe engine speed for the next lowest gear. The limits are 50 m.p.h. in third gear and 40 m.p.h. in second gear.

The third feature of the transmission is that any gear can be selected and retained—even top gear when starting from rest. The torque con¬verter will take up the drive smoothly and progressively and the car can be allowed to glide along quietly in traffic, without excessive gear changing and high engine revs. Since the kick-down is operative only when the lever is at D, full throttle can be used without causing a downward change when any of the other gear positions has been selected.

It will be seen that both the beginner and the enthusiast are admirably catered for by this transmission and if you are contemplating the purchase of a used model the higher cost of an "automatic" Mini would probably be more than justified.

Labels: acceleration, automatic, driver, gears, hydraulic, keen, minicar, transmission

Posted by Info Mini Cars at 04:49 0 comments

Steering and Roadholding

Expert drivers were quick to appreciate the light, precise steering and the excellent roadholding of these little cars, qualities which were subsequently demonstrated in many international road rallies, races and similar competitive events. Unlike many modern

Fig. 6. The Clubman Estate continues the popular series of Mini estate cars

cars, they should maintain an equal standard of stability when driven fast in gusty side winds.

Any lack of precision in the steering, or tendency to wander, therefore, calls for investigation. Similarly, instability when cornering fast or when the car is driven over a pot-holed surface at speed (the all-independent suspension normally deals exceptionally well even with atrocious road surfaces) suggests that the shock absorbers have weakened and are due for replacement.

A word of caution is, perhaps, advisable in the case of the estate car and van. The urge to forge ahead at too high a speed on rough tracks should be curbed if a full load is being carried, owing to the risk of the underside of the car bottoming on bumpy surfaces. This does not imply, of course, that the ground clearance is inadequate. At about 6£ inches (with the car laden) it compares favourably with many much larger models. A further point is that the disposition of the load can affect the handling qualities. It should be arranged as far forward as possible, since a tail-heavy car will develop an over-steering characteristic—a term which simply means that the tail will tend to swing outwards if corners are taken fast.

Braking System. The powerful and progressive Lockheed hydraulic brakes contribute to the excellent average speeds that can be put up during the course of a fast cross-country run when the car is being really hurried. Ordinarily, of course, it is bad practice to "drive on the brakes." When in good condition the brakes should call for only light pedal pressure during normal braking and moderately firm pressure to obtain maximum retardation, when the car should pull up all-square. The latter characteristic should be retained when the brakes become really hot through frequent use, and the travel of the brake pedal should not increase appreciably; in other words, the brakes are not prone to "fade" and if this symptom is detected, it is probable that incorrect linings have been fitted to the shoes at some time, or that the braking system as a whole requires a complete overhaul, as described in Chapter 10.

Assessing Performance and Fuel Consumption

Few subjects are more likely to provoke argument among rival owners than claims in respect of maximum and average speeds and m.p.g. figures. The only practical course is to tabulate some average figures which should be within the capabilities of a car that is in tip-top condition and on which the ignition and carburettor settings have been adjusted to a nicety, as described in other chapters of this book. These will be found in the Appendix.

In published road tests one often sees the 0 to 50 m.p.h. or 0 to 60 m.p.h. time quoted as a basis for comparison; but to obtain a really low figure in a standing-start test entails quite brutal engagement of the clutch at high engine revs and "snatching" of the gear changes—treatment which competition drivers accept as inevitable but which a considerate owner would hesitate to adopt. A less drastic test, and one which will give a reliable picture of the overall efficiency of the car, is to time the acceleration in third and top gears, from, say 20 to 40 m.p.h. or from 30 to 50 m.p.h.

As one would expect, a small car is appreciably livelier when only the driver is on board, as compared with a full load of passengers and holiday luggage. As a compromise, therefore, the figures given on page 147 relate to the performance that can be expected when a driver and one passenger are carried; the same applies in the case of the van, when it seems logical to assess the performance of this vehicle when carrying about half its maximum load.

The maximum speeds quoted for the indirect gears are the ultimate that can be reached, as opposed to the rather lower speeds at which one would normally change up during ordinary driving. Their chief value is an occasional check on engine condition; if the maximum obtainable in, say, second gear, falls appreciably short of the figure quoted, it is logical to suspect weak valve springs, sticking or burnt valves, retarded ignition timing or inefficient sparking plugs—faults which can be present even when an engine is otherwise in good mechanical condition and which can, fortunately, be put right quite easily by a practical owner.

Two further points deserve mention, before leaving the subject of performance. In the first place, the true maximum speed is always difficult to assess accurately. The best plan is to take the average of a series of runs in both directions over the same stretch of road, in order to cancel out the effects of wind and gradient. It is even more difficult to arrive at a true assessment of fuel consumption, as this can vary by as much as 5 m.p.g. below or 10 m.p.g. above the figures quoted, depending on road and traffic conditions, the load carried, the tyre pressures and the manner in which the car is driven.

Under most conditions, the car behaves quite well on ''mixture" grades of petrol, premium grades being an unnecessary luxury except during long, fairly fast runs in hot weather and when the car is heavily laden. The better grade of fuel will then tend to suppress any "pinking." If a "regular" grade must be used, an alternative ignition distributor is available which has a modified ignition-advance curve.

Labels: assessing, capabilities, consumption, cooper, deserve, figures, fuel, gears, maximum, mention, mini, performance, road, tests

Posted by Info Mini Cars at 04:46 0 comments

The Minis On The Road

We can now turn to an assessment of the road manners and handling characteristics of the cars or vans, mainly for the benefit of a driver who has no previous experience of these models and therefore lacks a yardstick by which to judge the performance of a particular car perhaps a used example that he has just purchased or is intending to put through a fairly comprehensive road test.

The points that will be emphasized are those that will give a fairly reliable indication of its general mechanical condition. It is impossible, of course, to lay down hard-and-fast standards, as so much will depend on the mileage that has been covered since new or since an overhaul was carried out. A certain amount of latitude must therefore be allowed, but it should also be remembered that, initially, these cars set a very high standard and will amply repay any work put in by a keen and conscientious owner.

The engine should be smooth and quiet, apart from a certain amount of "buzz" from the cooling fan as the speed rises, and a noticeable but not un¬pleasant whine from the constant-mesh gears that convey the drive from the engine to the gearbox, which are always in action, even when top gear is engaged (for details of a really worthwhile sound-damping kit, see Chapter 12).

Drivers of earlier models often criticized the gearchange on the score of stiffness in action, particularly "across the gate" between second and third gears. This tended to wear off, or at least become less noticeable, as the mileage mounted, and the change was, in addition, noticeably improved on later cars. As with many popular cars, difficulty is sometimes experi¬enced in engaging first gear when the car is at rest and as this gear is not synchronized on earlier cars, the double-declutching technique must be used when changing from second to bottom gear with the car on the move. In other words, the clutch must be momentarily engaged when the gear lever has been slipped into neutral, the engine at the same time being accelerated to synchronize the gears; the clutch is then depressed and the gear lever moved into the first-gear position.

The experienced driver will probably double-declutch even when changing between the upper ratios, since the synchromesh is not very powerful and can be overcome even when making moderately slow changes.

The baulk-ring synchromesh gearbox fitted to later models, however, was a great improvement and eliminated most of the complaints associated with earlier cars. Modifications to the remote-control gearchange on earlier Cooper models also cured the irritating rattle that developed at certain engine speeds, but as the nylon cup incorporated in the ball-and-

Fig. 5. The Austin Mini Countryman Mark II, counterpart of the Morris Mini Traveller

socket of the lever on later cars wears, the rattle can recur. The simple cure is to remove the gear lever and fit a second spring inside the existing spring. This will make gearchanging a little stiffer but will save a great deal of wear and tear on the driver's nerves!

While on the subject of troubles which develop in early Minis, the tendency to frequent breakage of the exhaust pipe cannot be overlooked. Owing to the design of the exhaust system, the pipe absorbs a considerable amount of the engine torque reaction, as the engine attempts to rock on its mountings. An engine tie-bar is fitted but when the bushes become worn the exhaust pipe eventually fractures, either at the manifold joint or at the bracket at the gearbox.

On pre-1964 cars, the remedy is to fit pairs of special cones, which are obtainable from most accessory shops stocking Mini gadgets, to the tie-bar bushes. The trouble is not likely to occur on later cars nor was it experienced on Cooper models, which have different mounting arrangements.

Finally, if you have an early model which is not fitted with the sixteen-blade fan, a lot of engine noise can be eliminated by substituting the latest pattern. It costs about £1, but you will have to remove the radiator in order to fit it.

Labels: assessment, declutch, double, drivers, engine, gearchange, mechanical, minis, quiet, road, smooth, stiffness

Posted by Info Mini Cars at 04:43 0 comments

Jacking the Car

Three different types of jack are used on the range of models. First, there is the screw-type, which fits into a socket approxi¬mately at the mid-point of the body sill, allowing each side of the car to be lifted with the front and rear wheels clear of the ground. Some of the earlier jacks caused alarm and despondency by buckling as soon as a load was placed on them but the sturdier replacements should not give trouble, provided that the jacking bar is inserted fully into the bracket. If this is not done the jack will be damaged and the bracket distorted.

If the sealing plug has been lost, it may be necessary to clear any accumulation of mud or grit from the socket to allow the projection on the jack to be pushed fully home. Fit a new plug at the first opportunity. If water is found on the floor of the car after driving in wet weather, make sure that one of the rubber plugs is not missing. The water can find its way into the hollow body sill and from there into the car.

The jack should lean outwards slightly at the top to allow for the tilting of the car as it is raised. To allow the central screw to be turned by the wheel-brace, it will be necessary to leave the door of the car open, which can be decidedly unpleasant for passengers in cold or wet weather. More-over the open door can, on occasion, constitute a very real traffic risk. These drawbacks may prompt some owners to carry a conventional screw-type or hydraulic jack which can be applied beneath the normal jacking point.

Never be tempted to jack at any other point, owing to the risk of damaging a body member or the underframe. Also, the situation does arise sometimes in which the desired wheel fails to leave the ground when the jack is fully extended. This calls for some redistribution of the weight in the car which will, of course, tend to pivot around the central jacking point!

Two other tips: make sure that the handbrake is fully applied and that the car is on firm, level ground. If the wheel that is to be removed is next to the kerb, make sure that there will be sufficient space to allow it to be drawn off its studs when it has been jacked-up.

When a ratchet jack is provided, a levelling bracket must be fitted to the pad on the jack, before jacking up the front wheels. The flanges of the bracket must be uppermost and its slot located over the tongue of the pad.

1. Brake drum

2. Steering swivel

3. Upper suspension arm

4. Suspension unit

5. Clutch operating lever

6. Starter solenoid switch

7. Heater water tap

8. Oil filler cap

9. Ignition coil

10. Vacuum ignition-control vapour trap

11. Radiator filler cap

12. Cooling fan

13. Dynamo or generator

14. Fan and dynamo driving belt

15. Radiator drain tap

16. Universal joint

17. Lower suspension arm

18. Transmission casing (engine sump) drain plug

19. Starter motor

20. Oil filter

Place the jack under the front crossmember on the side on which the wheel is to be lifted, as close as possible to the front flange. When a rear wheel is to be raised, the levelling bracket is not needed. Instead, the tongue of the jack must be engaged with the socket on the rear face of- the crossmember.

The third form of jack is the type in which the jacking arm is pivoted on a strut and is moved forward by turning a ratchet handle. First raise the head of the jack until it is in contact with the front or rear crossmember, on the side on which the wheel is to be raised, with the tongue of the jacking pad behind the front crossmember or engaged with the socket provided on the rear face of the rear crossmember, as the case may be. The pad can be raised quickly into position by rotating the milled nut on the end of the jacking screw. Fit the ratchet handle with the word "Raise" outwards and operate it to lift the wheel. To lower the wheel, take off the ratchet handle and reverse it so that the word "Lower" faces outwards.

Fig. 1. How it all began. An early Mini undergoing extensive tyre tests with the Dunlop test team. The operator is measuring the temperature of the front tyre treads after a spell of fast driving

It has been the experience of car manufacturers that a large proportion of drivers in the "family car" class neither require nor appreciate a full set of instruments. Consequently, on the less-expensive models the instruments have been reduced to two essentials, the speedometer and the fuel gauge. A green warning light ensures that any failure of the engine lubrication system will not be overlooked, and a red warning light similarly draws attention to failure of the dynamo to charge the battery and also reminds a forgetful owner not to leave the ignition switched on when the engine is not running. The functions of both these important warning lights will be discussed in more detail later. An owner who likes to have a more comprehensive set of instruments will be interested in the special instrument panels obtainable from accessory shops or the neat Smith's instrument sub-panel which can be mounted beneath the lower edge of the facia panel and which will carry two instruments from the Smith's 2-in. range: for example an oil-pressuregauge, water-temperature gauge, an ammeter; or one of these gauges paired with a dual gauge (oil-pressure and water-temperature, for example) thus giving three additional gauges. Provision is also made on the panel for an electric cigarette lighter.Ignition and Charging Warning Light. The red warning light incorporated in the speedometer dial should glow as soon as the ignition is switched on and when the engine is idling but should fade out when the dynamo begins to charge as the engine is speeded-up. If it continues to glow at normal running speeds, check for a slack or broken dynamo driving belt, especially if the light comes on suddenly during a spell of fast driving. As the belt also drives the fan and water pump, the sudden lighting-up of the warning lamp can enable one to spot the trouble before overheating occurs.

Labels: car, jacking, mini car care

Posted by Info Mini Cars at 04:37 0 comments

The Missing Starting Handle

A retrograde feature of the Minis which they share with many other modern cars is the lack of a starting handle. Most do-it-yourself owners will regret the absence of this useful item when carrying out many servicing jobs. A starting-handle kit is available which can be fitted by any owner who has an electric drill and is able to handle simple tools. This conversion will be dealt with in a moment, but in the absence of a starting handle what is the best method of turning the engine?

When it is simply a matter of making adjustments, the best plan is to remove the sparking plugs in order to relieve the pistons of compression pressures and to turn the engine by pulling on the fan belt. An alternative scheme when a manual gearbox is fitted is to turn the steering wheel to full right lock, jack up the offside front wheel, engage top gear and rotate the engine by turning the road wheel. Some owners adopt this method, as a last resort, to start the engine when the battery charge is too low to turn the starter motor but sufficient current remains to operate the ignition system. In such a case a quick twirl of the front wheel, after switching on the ignition and setting the mixture control, will usually produce a start but do make sure that the handbrake is applied really firmly and that the jack is secure. If the car should topple off the jack after the engine has been started the results might be disastrous!

The starting-handle kit just referred to is made by Oselli Engineering, Industrial Estate, Stanton Harcourt Road, Eynsham, Oxon. It is ingeniously arranged so that the handle can be inserted when the left front wheel is turned to full lock. It is necessary to cut an opening in the wheel valance and to bolt two guide plates in place to position the inner end of the handle. A bracket, bolted to the front suspension, steadies the outer end of the shaft. The only other job to be done is to unscrew the crank shaft-pulley securing bolt and substitute the starting-handle dog bolt, which is also provided in the kit.

On later models on which the starter motor is controlled by the ignition key, through a solenoid (electro-magnetic) switch in the engine compartment, it is possible to use an ingenious device known as the ETT 80A Junior Autopoints Unit, which was obtainable at the time of writing from Eldred Motors and Electronics Ltd., 15a Lincoln Road, Hull, E. Yorks. When this is connected-up to the battery and starter solenoid switch, the engine can be "inched" round at the slowest possible speed, making precise adjustment an easy matter.

The device is not expensive and if you intend to carry out home maintenance as a regular rule, it will soon repay its cost, as it can also be used to set the basic ignition timing, check the actual firing point of the engine, check the condition of the starter ring gear and for other purposes which are described in the instruction leaflet which accompanies the unit.

Labels: adjustments, eldred motors, handle, kit, mini car care, missing, retrograde, sparking plugs, starting

Posted by Info Mini Cars at 04:35 0 comments

Interior Heater

The earlier type of heater, fitted as standard on deluxe models and available as an optional extra on the remainder of the range, is of the simple recirculating type rudely termed a "fug-stirrer" in some quarters since it draws in and recirculates the air inside the car, instead of drawing in a fresh supply from outside. In hot weather the fan can be used for cooling purposes if the water supply to the heater is turned off by the tap at the hose connexion on the engine. Later heaters are of the fresh-air type and the tap is controlled from inside the car.

The fan motor will operate only when the engine is switched on. The initial movement of the switch brings the motor into operation at full speed. Further rotation reduces the speed (and the noise of operation) until the desired amount of heating and demisting is obtained.

Windscreen Wiper Switch:

The wiper blades are not self-parking on earlier cars. It is, therefore, necessary to switch off the wipers at the moment at which the blades reach the parked position.

Labels: eldred motors, fan, interior heater, mini car care, swicth, type of heater, windscreen, wiper

Posted by Info Mini Cars at 04:34 0 comments

Oil-pressure and Filter Warning Lights

Of equal importance is the green oil-pressure warning lamp which is fitted when an oil-pressure gauge is not provided. Like the ignition warning lamp, this should be extinguished as soon as the engine is running, as the contacts on the switch mounted on the engine are designed to open when the oil pressure in the lubrication system exceeds 5- 81b per sq in.

If the lamp continues to glow, the car should not be driven until the oil level in the sump has been checked. If all appears to be in order, and there is no sign of external leakage or clatter from the engine when it is cautiously speeded up, it is possible that the oil pressure-operated switch is faulty. Most garages will be able to test the switch and to check the pressure in the lubrication system by connecting a pressure gauge to the switch union. The normal running pressure is 40-70 lb per sq in.

On later models a second oil warning lamp is provided, which lights up only when the oil filter element is becoming clogged and is due for replace¬ment. The increased resistance caused by a dirty filter operates a switch on the filter housing.

Choke or Mixture Control. This control should be pulled out fully when the engine is started from cold but should be progressively returned as the engine warms up and is able to accept the weaker mixture without spitting-back or stalling in traffic. Keeping the mixture control in action

Fig. 3. The Riley Elf Mark III saloon. The Wolseley Hornet is very similar, apart from the radiator grille

too long will cause excessive fuel consumption and rapid cylinder wear.

On the other hand, since the carburettor is set to give an economical mixture strength when the engine is at its normal running temperature, misfiring and lack of power may be experienced if the mixture control is pushed home too soon after starting from cold; but the car should respond normally to the throttle after two or three miles have been covered, even in very cold weather. If it is necessary to keep the mixture control in use, carburettor adjustment, as described in Chapter 6, may cure the trouble. At the same time, check that the damper piston chamber in the carburettor is filled with the correct grade of engine oil.

Normally there should be no need to use the control when starting a warm engine; in fact, if the control is pulled out when the engine is hot, starting may be difficult or impossible, owing to the whole of the induction system being filled with an excessively rich petrol-air mixture. In such a case the only cure is to push the mixture control fully home, open the throttle wide and rotate the engine with the starter motor until the rich mixture has been cleared out of the cylinders. As soon as the engine fires, the throttle should be closed to prevent it racing.

Labels: cylinder, filter, fuel, lights, mini car care, oil, pressure, warning

Posted by Info Mini Cars at 04:34 0 comments

The Instruments and Controls

If the driving belt appears to be sound and correctly tensioned, failure of the lamp to be extinguished indicates a fault in the charging circuit, either in the dynamo, control box or wiring, which should be investigated at the earliest possible opportunity by a specialist. The reserve of current stored in the battery can be exhausted comparatively quickly, particularly when driving at night even if one forgoes the luxury of keeping the heater or radio in operation.

If the light does not glow when the ignition is first switched on, it is obviously essential to check the bulb in the warning lamp and renew it if necessary, or to trace and put right the fault in the circuit.

Fig. 2. The oil-pressure-operated warning light switch (1). The micrometer ignition-timing adjuster (2) is also shown

Labels: controls, ignition, instruments, light, oil, pressure

Posted by Info Mini Cars at 04:32 0 comments

Lubrication Equipment

Only two further items are necessary when lubrication is carried out at home. If an inspection pit is not available, a pair of wheel ramps will be required to provide adequate clearance for lubricating the front suspension, steering and the drive shafts, handbrake cables, draining the sump, and, incidentally, servicing the petrol pump.

Although the ordinary type of grease gun is quite efficient the side-lever type of gun is to be preferred. It enables a very high pressure to be developed with little effort, and has also the advantage of being fitted with a long extension tube, which makes it easy to reach less accessible points, and a snap-on hydraulic connector which provides a perfect seal without the need for applying pressure against the nipples.

These items will render the owner virtually independent of a service station, and their cost will probably be more than recovered during the first few months of home servicing.

A large-scale lubrication chart, printed on stout paper and suitable for hanging on the garage wall, is always an asset. It is worth recording that such charts, covering a very wide range of cars and models in addition to those covered by this book, can be obtained free of charge from the Castrol Chart Library, Castrol House, Marylebone Road, London, N.W.I.

Labels: chart, equipment, grease, gun, lubrication, pump

Posted by Info Mini Cars at 04:27 0 comments

Workbench and Storage

A workbench will be needed for any jobs that are not done in situ on the car, but is by no means essential if the work is confined to simple routine servicing and adjustments. It is quite possible to make do with a stout kitchen table, which can often be picked up for a few shillings at an auction.

Again, if any but elementary servicing is carried out, it will be necessary to obtain an engineer's vice, which should be securely bolted to the bench, reinforcing the top, if necessary, at this point. Excellent vices can often be obtained quite cheaply from stores dealing in Ministry surplus equipment.

Shelves can be fitted beneath the bench or to the wall, to accommodate the inevitable collection of tins, jars and bits and pieces that will accumu¬late from time to time. Small steel parts can be kept in jam jars filled with a fifty-fifty mixture of paraffin and engine oil, to protect them from rust. A wooden stand can also be made up to take a 5-gallon drum of oil as it is much more economical to purchase oil in bulk than in pint, quart or gallon tins. A draw-off tap can be purchased quite cheaply to replace the screwed plug in the side of the drum. Needless to say, when fitting the tap the drum should be laid on its side, with the screwed plug uppermost.

Labels: equipment, mini car care, storage, surplus, workbench

Posted by Info Mini Cars at 04:27 0 comments

Tools and Equipment

No job can be done properly if the correct tools are not available. Unfortunately, manufacturers of popular cars seldom include any but the bare minimum of items in the tool kit and it will therefore be necessary to purchase one or two items to supplement the selection of screwdrivers, pliers and so forth that the average home handyman will usually have accumulated over a period of years.

Spanners are particularly important, if any but the most elementary servicing is to be done. It must be remembered that "Unified" screw threads are standardized on these models and that nuts and bolts of this type call for the use of American spanner sizes (usually termed S.A.E. spanners). If you have a legacy of Whitworth spanners from an earliercar, do not be tempted to use them on Unified nuts. They may appear to be a reasonably good fit but there is a risk of damaging the corners of the hexagons if any stress is applied. It will be necessary to purchase a set of good-quality double-ended spanners in a range of sizes from, say TV in. to

in. A/F ("across the flats"), which will fit Unified nuts in sizes from i in. to & in.

Ring spanners are to be preferred, although one or two slim-jawed open-ended spanners may be required for the occasional awkwardly-placed nut. Better still is a set of socket spanners. If these are provided with an extension drive and, possibly, a ratchet handle, so much the better.

A medium-sized adjustable spanner will often come in handy but it should be used for holding, rather than turning, nuts and bolts. Always use a proper spanner whenever possible.

Before leaving the subject of spanners it should be mentioned that a B.S.F. nut should not be forced on to a Unified thread or vice versa. When buying replacements, make sure that these are of the Unified type; if these are not available, American National Fine (A.N.F.) threads are interchangeable, for all practical purposes, with Unified threads.

Next and equally important comes a set of feeler gauges. The small plug-gap and contact-breaker feelers provided in the tool kit may serve in an emergency but a combination set of feelers, which can be purchased quite cheaply from most accessory houses, enable adjustments to be carried out more accurately and more conveniently. A set of feelers is, in any case, essential when adjusting the valve rocker clearances. For the sparking plugs, however, wire-type gauges are preferable. These can be obtained in sets which incorporate a gap-setting tool which eliminates any risk of damaging the sparking plug electrodes, as described in.

A good tyre-pressure gauge is also a worthwhile investment, as it is seldom wise to rely on pressure gauges used by garages. In the first place, these are not always as accurate as they should be; and secondly, pressures should always be taken with the tyres cold, and this is obviously impossible if the car has to be driven to a garage or if pressures are checked during the course of a journey. The inexpensive telescopic type of gauge will serve quite well, provided that it is kept free from grit and protected against knocks. Better still, one may take a tip from rally and competition drivers and spend a little more on a dial-type gauge, which gives clearer and more accurate readings.

If one is starting from scratch it will be necessary to purchase a selection of screwdrivers, including one with a small blade for electrical work. The most economical plan is to buy a set, consisting of a handle and several interchangeable blades, fitted in a plastic wallet. Make sure that the set contains two different-sized Phillips screwdrivers to fit screws having cross-shaped recesses in their heads. A pair of side-cutting pliers and also the tapered, round-nosed type, will be needed, as will a ball-pane engineer's hammer and (although this is not essential) a hammer having both copper and rawhide striking faces, which will enable recalcitrant components to be dealt with without the risk of damaging machined surfaces.

An electric drill of the home-handyman type is, perhaps, something of a luxury, but the way in which it can speed-up a surprisingly large number of jobs, particularly if it is provided with the usual range of accessories, such as wire brushes for use in decarbonizing the cylinder head, a grind stone and a lambswool polishing mop, renders it a really worthwhile investment for an owner who carries out any appreciable amount of work.

Labels: equipment, spanners, tools

Posted by Info Mini Cars at 04:26 0 comments

Spreading the Work

Anyone who carries out the work at home will quickly discover the shortcomings of any conventional system of maintenance when he finds, for example, that at the official 6,000-mile service there are twenty-nine jobs to be done and that the work may well take up the better part of a weekend.

There is a lot to be said, therefore, for spreading the load by making a list of all the items that require attention and incorporating these on a chart in such a manner that two or three jobs can be done comfortably once a week say, during the course of an hour or so on a Saturday. The manner in which this is arranged will, of course, depend on the average weekly mileage but it is not difficult to devise a programme which will ensure that every item will recur at the appropriate period say, once in every 5, 10 or 20 weeks, as the case may be.

A further advantage of such a system is that it is flexible: if mileage should accumulate unexpectedly, it is a simple matter to bring the series of jobs forward by the appropriate amount. In practice, too, an enthusi¬astic owner usually spends a good deal of time at week-ends or in the evenings on tuning and adjustments so that a number of items receive more frequent attention than was anticipated by the manufacturer when drawing up the servicing schedule.

A final point: only experience can show, of course, whether or not it is necessary to vary the inspection periods on a given car. For example, worn steering swivels, which are still serviceable, will allow grease to escape more quickly than closely-fitting bearings and will require more frequent lubrication. The same applies to a greater or lesser extent to other aspects of maintenance.

The points at which lubrication and other routine attentions are required are shown in Fig. 8, but the more specialized aspects of servicing are dealt with in chapters devoted to the individual components. The routine checks that cannot be tied down to a strict schedule should not be forgotten; i.e. the engine oil and water levels and tyre pressures, which should be checked at frequent intervals, and always before starting out on a long run.

Labels: lubrication, spreading, work

Posted by Info Mini Cars at 04:25 0 comments

Maintenance Schedule

Earlier instruction books call for attention at intervals of 1,000, 3,000, 6,000 and 12,000 miles. There is a considerable body of technical opinion, however, to support the contention that most manufacturers' lubrication charts err on the side of safety, necessarily making allowance for the owner who tends to postpone routine servicing to the last minute. Provided that maintenance is carried out conscientiously, the periods between the various jobs can, in many cases, be appreciably extended. This is borne out by the fact that the current servicing recom¬mendations specify attention only at 3,000,6,000 and 12,000-mile intervals. On a car in good condition, in fact, it should not be necessary to lubricate the various chassis points more frequently than at 3,000-mile intervals unless it is operating under very adverse conditions of heat and unsurfaced roads, or continuous mud and slush.

Fig. 7. An under-bonnet view of the Mini. Many of the items requiring servicing are to be found in the engine compartment. The arrangement is typical of most of the range of Minis

Dynamo-charging regulator and cut-out

1. Brake fluid reservoir

2. Clutch fluid reservoir

3. Carburettor air-intake filter

4. Carburettor

5. Oil filler cap

6. Thermostat housing

7. Windscreen wiper

9. Radiator filler cap

10. Windscreen washer water supply

11. Clutch-operating cylinder

12. Ignition coil

13. Ignition distributor

14. Sparking plug

15. Dynamo or generator

16. Cooling fan

The only exception to the general rule concerns the question of changing the engine and transmission oil. An oil change should not be deferred beyond the 6,000-mile limit if a manual transmission is fitted and 3,000 miles if the car has an automatic transmission; it may, in fact, be advisable to change the oil more frequently when the car is operating under adverse conditions, such as frequent cold starts and short runs.

Labels: charging, dynamo, maintenance, regulator, schedule

Posted by Info Mini Cars at 04:24 0 comments

Maintenance in the home garage

It is understandable that a practical owner should wish to carry out as much of the routine maintenance on his car as possible but how much of the work would it be wise for him to tackle ? The answer depends on his experience and the facilities at his disposal (appropriate tools and equipment will be discussed later in this chapter).

It may be preferred to leave routine lubrication and sump drainage (at best a somewhat messy job) to the nearest garage, if the use of a ramp or pit is not available. Even a novice, on the other hand, should be able to tackle with confidence any of the simpler routine adjustments and servicing described in Chapter 4, while the more experienced owner will go on to the jobs dealt with in subsequent chapters. No great degree of skill is required; if the work is done by a garage it is the man-hours that cost money. Labour charges, in fact, form the major part of most service and repair bills nowadays.

There is every incentive, therefore, to tackle as much of the work as possible, preferably including routine lubrication. Even if it is necessary to purchase a pair of wheel ramps and a grease gun, the moderate outlay will quickly be recovered and one has the satisfaction of knowing that the work has been done conscientiously, that no greasing points or adjustments have been overlooked or scamped and also that any signs of impending trouble have been detected in good time. Apart from a saving of upwards of £20 during a year (more, perhaps, if a large mileage is covered) the do-it-yourself owner is also freed from the need for making an appointment to have his car serviced (sometimes weeks in advance) and being deprived of its use for the better part of a day while it awaits its turn for attention in a busy service station.

Labels: drainage, garage, home, lubrication, maintenance, sump

Posted by Info Mini Cars at 04:20 0 comments

Lubricating the Speedometer Drive

The flexible cable that drives the speedometer should be lubricated at 12,000-mile intervals, or at an earlier stage if the speedometer needle begins to flicker or gives an unsteady reading. Unscrew the sleeve that connects the outer casing of the drive to the rear of the speedometer (Fig. 44 shows the arrangement used on most models), and pull the inner cable out of the casing. Lightly smear the cable with grease, insert it fully into the outer casing and then withdraw it about six inches and wipe the exposed section clean before again pushing the cable fully home into the casing. If this precaution is neglected, or if the cable is heavily coated with grease, there is a risk of the lubricant finding its way into the speedometer itself, necessitating the dismantling and cleaning of the instrument by a specialist.

Before reconnecting the cable to the speedometer, make sure that its lower end is fully home in the driving union by rotating the cable with the fingers while pushing it home. The square end should stand clear of the casing by approximately f in. Similarly, when reconnecting the cable to the speedometer head, check that it engages with the driven spindle in the speedometer and do not use force when tightening the retaining sleeve.

When sound-insulating felt is applied to the engine bulkhead it will be necessary to slit the felt carefully around the speedometer cable to enable the sleeve to be unscrewed. After the cable has been reconnected, seal the slit in the felt with a strip of fabric, smeared with a good adhesive such as Bostik 2.

Labels: lubricating, speedometer drive

Posted by Info Mini Cars at 04:17 0 comments

Rear Hub Lubrication

Another job which is necessary at the 6,000-mile period is to check the lubrication of the rear wheel hubs. Remove the wheel disk and prize off the grease cap from the end of each hub, using two screwdrivers and taking care not to distort or damage the cap. If there is no grease in the cap, half-fill it with the correct lubricant (see the Appendix) and tap it gently back into place. The front hubs are packed with sufficient grease to last until an overhaul eventually becomes necessary.

Labels: hub, lubrication, rear

Posted by Info Mini Cars at 04:17 0 comments

Lubricating the Water Pump

The small plug which seals the lubrication point on the water pump, just behind the fan pulley, is apt to be overlooked. When carrying out the 6,000-mile service, this plug should be unscrewed and a few drops of SAE 140 gear oil should be dripped into the opening. It is important not to force in oil or grease with the grease gun and not to overlubricate the pump, as excess oil will find its way past the bearings on to the face of the special carbon sealing ring, reducing its efficiency.

Labels: lubricating, pump, water

Posted by Info Mini Cars at 04:16 0 comments

Miscellaneous Oil-can Attentions

The dynamo requires only two drops of engine oil in the lubrication hole provided in the bearing plate at the opposite end to the driving pulley. The bearing at the pulley end is self-lubricating. Similarly, the starter motor needs no lubrication until the time eventually comes to dismantle it for a general examination and overhaul.

Items such as door hinges, the bonnet lock and operating mechanism and the boot lid hinges should not be overlooked. Wherever there is any likelihood of oil coming into contact with passengers' clothes, the surplus should be wiped away immediately. To avoid this risk the door lock tongues and catches can be lubricated by rubbing them with an ordinary wax candle.

Labels: attentions, dynamo, hinges

Posted by Info Mini Cars at 04:16 0 comments

Lubricating the Handbrake Cable Guides or Sectors

It is particularly important to keep the handbrake cables of early models well lubricated where they pass through the cable guide tubes fitted to the rear radius arms. Otherwise, the brakes are inclined to bind or the cables may freeze in the guides. To do the job properly it is advisable to slacken off the adjusters at the forward ends of the cables so that a generous coating of grease can be applied to the cables and tubes.

On later models the cables pass around pivoted sectors, the pivots of which must be lubricated with light engine oil. On still later models a self-lubricating bush is fitted to each sector, but this does not entirely eliminate the risk of the brakes binding and if this is experienced the bush should be sparingly lubricated with engine oil, as in the case of the earlier models.

Labels: cable, guides, handbrake, lubricating, sectors

Posted by Info Mini Cars at 04:15 0 comments

Lubricating the Distributor

Again one is working in rather cramped quarters, and since lubrication should be accompanied by a check of the condition of the contact-breaker points and readjustment of the gap, if necessary, there is a lot to be said for removing the front grille, thus rendering the distributor immediately accessible (and, incidentally, con¬siderably simplifying the work of changing the oil filter element). Alter-natively, the distributor may be removed from the engine, as described in Chapter 7.

Remove the moulded cap from the distributor by springing aside the two retaining clips. The rotor should then be pulled off the end of the central shaft, exposing a screw within a recess in the shaft to which a few drops of thin engine oil should be applied. It is not necessary to remove the screw; a clearance exists between it and the inner face of the spindle through which oil can reach the spindle bearing.

While the rotor is off, lightly smear the faces of the cam with a very small amount of grease. Over-lubrication should be avoided owing to the risk of grease being thrown on to the contact points, where it will become carbonized and cause misfiring. A few drops of light engine oil should also be squirted through the hole in the contact-breaker base-plate through which the distributor spindle passes and just a spot of oil should be placed on the pivot pin on which the moving contact arm swivels. Again over-generous lubrication can do more harm than good.

Do not forget to replace the rotor and make sure that the driving lug on its underside engages correctly with the slot in the spindle. Push it home as far as possible.

Labels: distributor, lubricating, moulded cap

Posted by Info Mini Cars at 04:14 0 comments

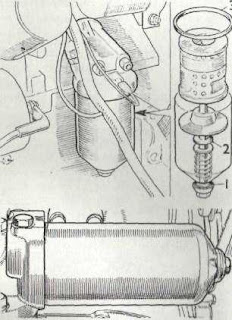

Changing the Oil Filter

If the warning light provided on later models (see pages 4 and 5) glows before the recommended mileage has elapsed, the filter should be changed within the next 300 miles.

If an early filter change has been carried out, however, and only a thousand miles or so have elapsed before the normal 6,000-mile service falls due, there will be no need to change the filter again at this service; it can be left to run its full 6,000 miles, unless the warning lamp lights up after a shorter period.

Normally, the filter casing is removed by working from beneath the car, but it is easier to remove the radiator grille. This is necessary, in any case, when changing the horizontally-mounted filter on automatic-transmission models. Shops which sell Mini accessories can usually supply two special retaining nuts which allow the grilles on most models to be removed quickly and easily a worthwhile modification for the owner who does his own servicing, as it also makes it easier to work on the ignition distributor.

Before removing the oil filter, clean the exterior of the casing as thoroughly as possible before removing the central retaining bolt. The filter retaining bolt can then be unscrewed, holding a tin beneath it to catch the oil which will drain from the filter as the bolt is withdrawn. The casing can then be removed.

The new element will be supplied complete with new sealing washers. Although most instruction manuals, and the leaflet enclosed with the element, recommend that the sealing washer in the casting, against which the upper edge of the filter bowl seats, should be renewed, it is a tricky job to fit the new washer evenly into its groove.

If the old washer appears to be in good condition, therefore, it is best to leave well alone. Only if an oil leak becomes apparent when the filter is reassembled and this cannot be corrected by slackening the bolt and repositioning the filter, should the washer be renewed. To do this, the simplest plan is to remove the filter bracket from the crankcase by undoing the oil pipe connexion and the two retaining screws. If the gasket between the flange of the bracket and the crankcase is damaged, a new gasket should be fitted at this point.

Assuming that a straightforward exchange of the filter element has been carried out, however, the filter bowl should be thoroughly cleaned before the new element is inserted and the small felt washer must be positioned between the element pressure plate and the metal washer above the pressure spring. To ensure correct oil filtration it is particularly important that this washer should be in good condition and a snug fit on the central securing bolt. After the bowl has been manoeuvred into position beneath the bracket and the central securing bolt inserted, hold the head of thebolt up against the bowl and fill the bowl with oil to ensure that oil will reach the bearings as soon as the engine starts. For the same reason, do not operate the starter while the filter is off or the sump empty, as this will empty the oil pump and the oilways, possibly resulting in considerable delay in building up pressure when the engine is restarted.

As soon as the engine is running, examine the filter for leakage. A very pronounced oil leak will occur if the bowl is slightly displaced and does not seat squarely on the sealing ring.

Labels: changing, mini car care, oil filter

Posted by Info Mini Cars at 04:13 0 comments

Changing the Engine Oil

The engine oil becomes contaminated with carbon and other products of combustion, including condensed water and fuel, and must, therefore, be drained out at least at 6,000-mile intervals for cars fitted with standard transmissions and at 3,000-mile

Fig. 10. The oil-pressure relief valve

intervals for automatic-transmission models. If the engine is worn, the degree of gas leakage past the piston rings may make it advisable to change the oil more frequently; for example, at 3,000 miles for standard-transmission models and, say, 1,500 miles when an automatic transmission is fitted. Also, more frequent changes are advisable when most of the driving is done in cold weather, particularly when frequent starts are made from cold and when the engine is allowed to idle for long periods. At the other extreme, in hot, dusty conditions the oil will deteriorate more quickly than in temperate climates. Under adverse conditions it may be advisable to change the oil as frequently as every 1,000 miles. If in doubt, consult your local B.L.M.C. dealer.

The oil should be drained when the car has just come in from a run; being hot, it will be more fluid and will be holding in suspension the impurities. At the same time the oil filter element should be cleaned or, preferably, renewed.

If a modern premium oil is used, it should not be necessary to flush out the sump with flushing oil, as was often recommended with older types of car. As the sump may contain up to nine pints of oil, a sufficiently

While the oil is draining, examine the drain plug. This is unusual, as it incorporates a magnet which will attract and hold the minute iron and steel particles that must inevitably be worn off the gears, and which might otherwise damage the engine if the oil filter were allowed to become clogged to such an extent that the filter by-pass valve opened.

Labels: changing, engine oil, mini car care

Posted by Info Mini Cars at 04:12 0 comments

Topping-up Carburettor Piston Damper

In the neck of the suction chamber that forms the upper part of the carburettor is a small hydraulic damper, consisting of a piston, fitted with a one-way valve and working

Topping-up the carburettor piston damper

in an oil-tilled recess in the top of the carburettor piston rod. The resistance created by oil flowing past the small damper piston prevents the carburettor piston rising too quickly when the throttle is suddenly opened. This would cause an unduly weak mixture, since the flow of petrol from the carburettor jet always tends to lag behind the flow of air through the carburettor. Consequently, if the damper chamber contains insufficient oil, a "flat spot" will be experienced when the throttle is opened suddenly and the engine may spit back when full acceleration is demanded. The hydraulic damper also prevents the piston "fluttering" under certain running conditions.

It should be a routine matter, therefore, to check the level of the oil in the dashpot when going around the other items with the oil can filled with SAE 20 oil.

On no account use thin machine oil, which is suitable only to lubricate the piston rods of earlier types of S.U. carburettors which did not have oil dashpots. The point is stressed because some garage mechanics do not seem to be aware of the distinction. If the performance is sluggish or "spitting back" occurs when the throttle is suddenly opened and the engine is at its normal operating temperature, check that the right grade of oil has been used in the dashpot.

In Fig. 6 the damper rod has been removed. If the oil filler cap has an air-vent hole drilled in it, the oil level should be about \ in. above the top of the hollow piston rod. If there is no vent hole in the filler cap, the oil level should be \ in. below the top of the hollow rod.

Labels: carburettor, damper, piston, topping-up

Posted by Info Mini Cars at 04:07 0 comments

Checking Engine Oil Level

The oil level should be checked with the car standing on level ground. A few minutes should be allowed for oil to drain back to the soimp to prevent a misleadingly low reading being shown. Remove the dipstick, wipe it, return it and push it fully home before withdrawing it to check the level. It is more economical to keep the sump well topped-up than to allow the level to fall to near the danger point, at the end of the dipstick, before restoring the level.

Labels: checking, engine oil, level

Posted by Info Mini Cars at 04:03 0 comments

Grease-gun Lubrication

The most suitable lubricant to use in the grease gun is one of the modern multi-purpose lithium-based greases, which are suitable not only for the steering connexions, swivel pins, propellor-shaft nipples, brake cables and pivots, but which also should be used for packing the rear wheel hubs. If it is blended with molybdenum disulphide, so much the better.

Each grease nipple should be wiped before the gun is applied, to avoid any risk of grit being forced through the nipple into the bearing.

If the nipple is dented or otherwise damaged it is a simple matter to unscrew it and fit a replacement, which can be obtained from a B.L.M.C. dealer. In an emergency, however, it is possible to obtain a satisfactory seal, even on a damaged nipple, if a piece of cheesecloth or other light fabric is first placed between the nipple and the end of the grease gun.

Many owners are unaware that every lubrication nipple contains a small spring-loaded ball valve which prevents the grease from escaping from the bearing. If a "worm" of grease exudes from the nipple when the grease gun is removed this valve is not functioning correctly and it is advisable to renew the nipple as soon as possible.

It is an advantage when greasing each steering swivel to jack up that side of the car until the front wheel is clear of the ground. This will allow grease to reach the thrust faces of the bearings that carry the weight.

Early in the life of the Mini the greasers on the inboard propellor-shaft splines, which were difficult to reach, were rendered unnecessary by packing the joints with a special long-life grease. The lubricator on the gear linkage, at the back of the engine, now qualifies as the only nipple which is rather inaccessible but the latest recommendation is that the linkage needs lubrication only at major overhaul periods, unless unusual stiffness develops in the gear change.

A further example of improvement in servicing is the substitution of nylon ball cups for the metal-to-metal type previously used at the ends of the steering tie rods. The later design of joint does not require lubrication and is not therefore fitted with a grease nipple.

Having disposed of the general aspects of lubrication one can now turn to one or two points that deserve a little clarification when tackling the jobs listed under the various mileage headings in the Maintenance Schedule.

Labels: grease, gun, lubrication

Posted by Info Mini Cars at 04:03 0 comments

When the Oil Warning Light Glows

The oil-pressure switch on the crankcase normally opens when the pressure in the system exceeds 5-8 lb per sq in., so that the green warning light should be extinguished whenever the engine is running. If the light continues to glow or suddenly comes on at normal running speeds, the cause (apart from a faulty pressure switch, which is a possibility that cannot be entirely ruled out) is either a dangerously low oil level in the sump or loss of pressure at some point in the system.

If an oil pressure gauge and adaptor are substituted for the switch, a pressure of at least 40 lb per sq in. should be recorded when the engine is thoroughly warmed-up and running at a fairly fast speed; about 15 lb should be shown at idling speed. Incidentally, it is possible to fit an oil gauge and at the same time to retain the warning light if the oil-pressure switch is replaced by a special oil-filter adaptor, to which the pressure gauge pipe can be connected.

Assuming that the sump is full and that the correct grade of oil is used, low oil pressure can be caused by a choked intake in the sump, a faulty oil-pressure relief valve or a worn pump.

Fortunately the pump is seldom at fault (except when the engine has covered a very large mileage). The oil-pressure relief valve is, however, a possible culprit. This valve, which opens at 70 lb per sq in., relieves the excessive pressure that would otherwise be developed in the system when the oil is cold, is retained by a hexagon plug beneath the oil-pressure switch (see Fig. 10). The valve should be removed and cleaned. The seating in the cylinder block should also be cleaned with a lint-free cloth wrapped around the end of a length of wood. If the strength of the spring has weakened a new spring should be fitted. The valve is not adjustable.

If satisfactory pressure is not restored when the above points have been attended to, the crankshaft and connecting-rod bearings are probably badly worn.

Labels: light glows, mini car care, oil warning

Posted by Info Mini Cars at 04:02 0 comments

Engine and Transmission Lubrication

On conventional cars the engine oil has only to lubricate the engine itself. The gearbox and the final-drive gears in the rear axle have their own supplies of lubricant which, unlike the engine oil, are not subjected to extremes of heat, dilution by condensed fuel and contamination by carbon particles and by acid moisture. On the Minis, however, the engine, "gearbox" and final-drive gears share a common supply of oil, since all the gears and the differential are carried in the crankcase beneath the crankshaft.

It should not be necessary to emphasize, therefore, that "cheap" oils are likely to be the most expensive in the long run. Similarly, any temptation to delay oil changes beyond the recommended mileage is likely to result, sooner or later, in "expensive noises."

This is particularly important when an automatic transmission is fitted. Other types of automatic gearboxes normally call for the use of a special fluid but extensive tests have shown that normal engine oil can be used satisfactorily in the Mini automatic transmission provided that the oil is changed regularly at 3,000-mile intervals and that the oil filter is renewed at least at 6,000-mile intervals and more frequently if the warning light glows. After the specified mileage, changes begin to take place in the engine oil which alter the friction characteristics of the clutches and epicyclic brake bands in the transmission, upsetting the smooth operation of these units.

Owners of new Minis are sometimes worried by heavy oil consumption during the first few thousand miles. Oil may disappear at the rate of a pint in every 150 miles but experience has shown that after about 3,000 miles the piston rings should have bedded-in and the consumption should drop to a much more reasonable figure. By the time that about 5,000 miles have accumulated, for example, it should not exceed about 500 miles to the pint, although Mini-Cooper engines arc rather more thirsty if they are driven hard. Early Coopers, incidentally, gained a reputation for very heavy oil consumption but modifications which were incorporated in later versions reduced their appetite to a more acceptable figure.

Owing to the fact that the engine is not shielded by a warm radiator from the flow of air through the front grille, a good deal of sludge tends to form on the valve rocker gear and inside the rocker cover. This can be prevented by drilling two ,?, in. holes in the oil filler cap; but do not do this if a special crankcase ventilation system is fitted . It also helps to blank off the grille during the winter months.

Labels: engine, lubrication, transmission

Posted by Info Mini Cars at 04:01 0 comments

Lubrication

Effective lubrication can be summed-up as the use of the right kind of lubricant, in the right quantity, in the right place and at the right time. Armed with the diagram on page 19, or, better still, a large-scale Castrol wall-chart , even the novice would find it difficult to go far wrong. There are, however, a number of "whys" and "wherefores" which are worth explaining in a little more detail and some practical tips which will enable certain jobs to be carried out more effectively and may forestall trouble at some future date more especially in view of the unorthodox construction of the Minis.

The equipment which will be required when lubrication is to be carried out in the home garage has already been described. We can begin, therefore, with the all-important subject of lubricating the combined engine and transmission unit.

Labels: lubrication

Posted by Info Mini Cars at 03:59 0 comments

Saturday 17 October 2009

Crankcase Ventilation System

On later models a special crankcase-breather system is fitted. The engine fumes are drawn from the crankcase, through aflame-trap and a ventilation valve, into the inlet manifold. The valve regulates the flow of air and fumes into the manifold, thus preventing excessive weakening of the mixture when the engine is idling. Clean air is drawn into the engine to replace the fumes, through a filter which is incorporated in the oil filler cap. This cap should be renewed as a complete assembly after 12,000 miles in service, or earlier if it becomes clogged.

To test the system, take off the oil filler cap when the engine is running at idling speed, at normal operating temperature. If the valve is functioning correctly the engine will speed-up by approximately 200 r.p.m. (which represents an audible change in engine speed) when the cap is removed.

If there is no change in the idling speed, remove the spring clip from the ventilation valve and dismantle the valve as shown in. Clean the metal parts with petrol. Hard deposits on these parts can be softened by dropping the parts into boiling Vater for a few minutes.

The diaphragm must be in good condition. If in doubt, replace it. Do not stretch or distort the spring. When reassembling the valve, make sure that the metering needle is correctly centred and that the diaphragm is seating properly before refitting the cover and spring clip.

Labels: crankcase, ventilation system

Posted by Info Mini Cars at 04:07 0 comments

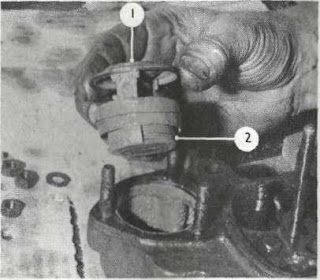

The Thermostat

Although the thermostat which regulates the cooling water temperature vitally affects engine efficiency it is often overlooked and seldom checked. As can be seen from Fig. 16, it consists of a valve, fitted at the water outlet from the cylinder head, that prevents circulation of water to the radiator until the normal running temperature is reached.

The bellows, filled with wax or a volatile liquid, begins to expand at a temperature of 82°C, in the case of the standard model. An alternative thermostat which opens at 88°C can be substituted during cold weather. The higher opening temperature of the latter improves the efficiency of an interior heater and can also cause an appreciable improvement in fuel consumption during winter driving. A thermostat which opens at 74°C is available for use in hot climates.

Thermostats, of course, are not infallible and if overheating occurs, or conversely, if the engine is slow to warm-up, it is logical to check this item. Remember, however, that overheating can be caused by a number of other faults, among which deposits of rust and lime scale in the cylinder head and radiator water passages are the most likely. Shortage of oil or water, obstructed air passages in the radiator, over-retarded ignition and severe pinking will also cause the trouble.

The thermostat can be lifted out after the water outlet elbow has been removed. When cold the valve should be tightly closed. If it is open, either the bellows is punctured or the stem is jammed by an accumulation of lime deposits.

If the thermostat appears to be serviceable, it should be tested by immersing it in a pan of water which should be brought nearly up to boiling point. If a suitable thermometer is available the opening temperature should be checked while moving the thermostat about in the water to ensure even heating; the temperature will, of course, depend on the type of thermostat fitted, as described above. If the valve has not opened when the water begins to boil a replacement thermostat should be fitted. Before refitting a used thermostat make sure that llie small air-release hole in the valve is not choked; otherwise an air-lock is likely to occur when the cooling system is refilled.

Labels: thermostat

Posted by Info Mini Cars at 04:06 0 comments

Descaling and Flushing Cooling System

At least once a year preferably in the autumn and in the spring if an anti-freezing compound is used the system should be drained, flushed-out and refilled. If the water does not flow freely from the radiator drain tap and from the tap on the side of the engine cylinder Wock (both are accessible from inside the engine compartment) the openings should be probed with a piece of wire to dislodge any accumulated sediment or better still, unscrew and remove the taps. A hose should then be inserted in the filler neck and water allowed to flow through the system until clean water issues from the taps.

Before flushing the system it is an advantage to run the car for a day or two with a proprietary non-corrosive compound added to the cooling water. These compounds will remove any deposits of rust or scale which might be sealing minor leaks. If anti-freezing compound is used without descaling the system, there is a risk that its very "searching" action may find such weak spots, with possibly serious consequences if a leak should develop and continue undetected during the course of a lengthy run.

If an interior heater is fitted and the cooling system has been drained, make sure that the heater water-control tap is open when refilling the radiator. It is a good plan to slacken the clamp on the radiator end of the heater hose when a recirculatory type of heater is fitted, and to loosen the hose in order to dispel any air-lock, that may develop in the heater. Do

The "anti-smog" crankcase ventilation valve ,1tted to some models. The valve should be cleaned with methylated spirits at 12,000-mile intervals

1. Spring clip

2. Cover

3. Diaphragm

4. Spring

5. Control orifice

not tighten the clamp until water is flowing from this point and re-check the level in the header tank after the engine has been running for a few minutes.

Labels: cooling system, descaling, flushing

Posted by Info Mini Cars at 04:05 0 comments

Transmission Couplings

The universal joints at each end of the two drive shafts should be checked during the 6,000-mile service. The rubber couplings at the inner end of the shaft may fail within 5,000-6,000 miles if oil is allowed to leak on to them, but can have a life of upwards of 30,000 miles if they are kept free from oil and the U-bolts are correctly tensioned. The self-locking nuts on the U-bolts should be tightened until two threads protrude. If they have been too slack or too tight for any length of time, the rubber cross-pieces in the couplings will have been damaged and should be renewed. It is as well to renew the self-locking nuts at the same time, and as the new bolts are quite cheap, it will do no harm to replace these also.